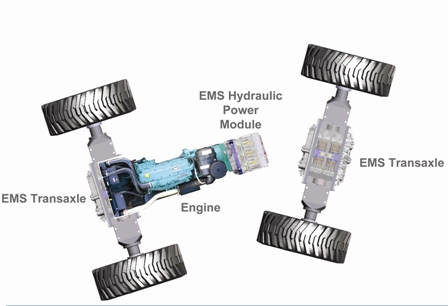

Haldex Hydraulics has chosen BAUMA (stand 508 in Hall A4) to launch EMS, a revolutionary total vehicle management system which provides more efficient and economic operation of all powered functions in a wide variety of mobile equipment from wheel loaders and excavators to lift trucks.

Other hydraulic hybrid systems capture braking energy, store it and redeploy the stored energy for propulsion. Haldex EMS is the only hydraulic hybrid that provides energy management for the implement and superstructure swing as well as propulsion functions. The Haldex system is designed to manage energy and transfer it simultaneously to any function within the vehicle and at any time, so drastically reducing fuel consumption, engine and component wear, whilst enhancing load control, boosting productivity and overall vehicle efficiency.

The whole system works by converting inertia energy to fluid energy during the braking and implement cycles and simultaneously using it for other functions or storing it within a central accumulator. The vehicle’s hydraulic circuits are mechanically coupled via pump/motor units but operate completely independently. Energy transfers are not serial or subject to a hierarchical protocol, which means that energy recovered from one function does not need to be stored before it can be used in another. Closed loop electronics allow more precise control of energy conversion so minimizing waste.

In an EMS vehicle, the engine is completely decoupled from the wheel drives and the implement hydraulic circuits, allowing it to operate at peak efficiency throughout the duty cycle. Unlike valve control systems, Haldex EMS does not convert load energy to heat, which of course is then wasted. The ability to distribute the engine’s power output with maximum efficiency throughout a vehicle’s operational functions offers other potential benefits such as down-sizing the engine, optimizing its rating, or developing an engine-off and engine-idle strategy. Energy from the engine can also be coupled with stored energy and deployed to any function to enhance its operation. This capability can provide greater break-out force for an implement or more rapid acceleration of the vehicle. In addition traction control and anti-lock braking, to eliminate wheel slip and skidding are integrated into the EMS control technology.

The introduction of Haldex EMS is timely, as there is increasing regulatory pressure across the globe for lower emissions and lower fuel consumption. Depending on the vehicle’s configuration and specific duty cycle, the system can deliver very considerable benefits in all these areas, notably savings in fuel consumption in excess of 50%. In addition, there is the potential for increased platform safety, increased vehicle performance and productivity, together with reduced life-cycle costs. Compared with parallel hybrid systems, fewer components are required, while increased reliability lessens the warranty burden characteristic of electric hybrids.

MHW Magazine News and stories from the Materials Handling Industry

MHW Magazine News and stories from the Materials Handling Industry