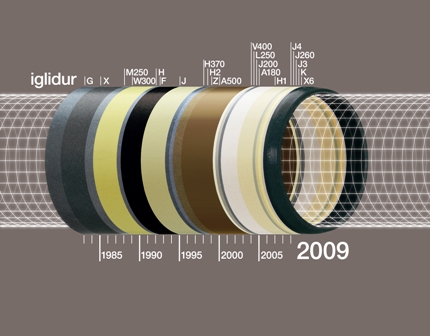

Exactly 25 years ago in 1984, the year Apple introduced the Macintosh, the polymer plain bearing specialist igus began their material research. In addition to the thinner wall thicknesses that were easily achievable through injection moulding, new materials were continually being developed from this point onwards, all based on compounded material. The iglidur plastic plain bearing range was born: to date lubricant and maintenance-free machine components have successfully replace millions of metal bushings that required oil or grease. Also, igus introduced the system of calculating the service life of plastic plain bearings. "igus is not the inventor of the plastic plain bearing," says UK Bearings Director Matthew Aldridge, "strictly speaking, this was related to the discovery of the properties of nylon. But our company is certainly the one that pushed the trend towards modern polymer plain bearings the hardest."

Today, igus has the largest range of tribo-optimised plastic plain, pivoting and linear bearings in the world. The company supplies more than 10,000 bearing parts ex stock, with 29 different catalogue materials for almost every application. The spectrum ranges from all-rounders through FDA approved bearings to high-temperature and underwater bearings. The indestructible iglidur high-performance plastics have undergone continual testing with more than 8,000 tests every year for durability, friction and wear. Over the last 25 years, this has led to the creation of a unique company database containing the tribological properties of polymers.

Pushing application limits new iglidur J3 and iglidur X6

The latest compounds are being generated with the help of cutting-edge knowledge from material science, then thoroughly tested and brought to maturity for market launch.

Matthew Aldridge: "We want to continually push the application limits for polymer plain bearings." The company has now launched the new materials iglidur X6 use of nano particles which are up to six times more wear-resistant at high temperature than iglidur X and iglidur J3 300 percent lower wear rate than iglidur J. In time for the iglidur Silver Jubilee