At the LogiMAT (Stuttgart, 10th to 12th February 2015) in hall 1, booth

1A31, ABM Greiffenberger Antriebstechnik GmbH presents an excerpt of the

company’s extensive portfolio from the areas storage techniques, forklift

trucks and e-mobility. Among other things, a new controller for the

storage sector will be on display. It is versatile and enhances the

processes in the container conveyor technology.

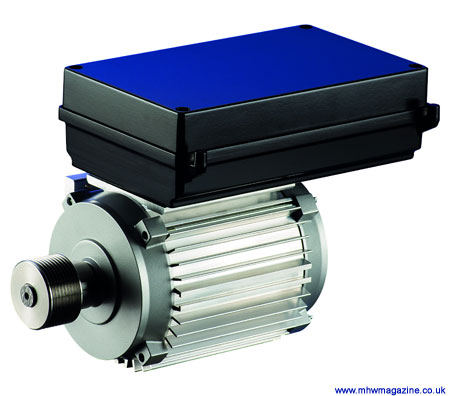

26.11.2014 – For the time being, the new controller has been designed for

a motor power of 0.75 kW and works without any problem at temperatures

from -30° up to +50°C. The sensorless control has been perfectly adjusted

to the ABM Sinochron motors. Pluggable connections can easily be reached

from outside and several drives can be operated from one power supply.

Users adjust the necessary parameters by means of Near Field Communication

(NFC) via PC or Smartphone-App. The service-friendly controller has been

designed for the direct assembly to the motor. Alternatively, it can be

attached to the wall, separated from the motor. Its very compact design

with aluminium die-cast housing allows an easy, quick installation. The

ABM innovation can be used in many intra-logistics applications of the

container conveyor technology in roller conveyors, belt conveyors or

curved conveyors.

Energy-efficient Sinochron Motors

In the area of storage logistics, ABM Greiffenberger shows

energy-efficient Sinochron motors as compact drive units for roller

conveyors. They work with a high process reliability at temperatures of

-30° up to +45°C and are therefore also suited for the use in deep-freeze

rooms. Sinochron motors reach highest efficiencies in the part-load

operational range and are that way lowering the energy costs. The drive

unit without gearbox provides a top plant availability. It moves mobile

loads of up to 180 kilogram and reaches conveying velocities of 0.3 up to

1.2 m/s.

Maintenance-free and easy to install angular gear units

Two-stage angular gear units of the KG-series of ABM with nominal torques

of up to 700 Nm will also be on display. They are maintenance-free and

easy to mount because of their angular design. The gearboxes are available

in two executions, full shaft and hollow shaft. They are suited for the

assembly to asynchronous or Sinochron motors. The KG-series, made of

aluminium die-cast (Al 230), has a smooth, dirt-repellent surface and

convinces with a high corrosion resistance.

The shaft-mounted helical gear units of the FGA-series of ABM have been

designed for an output of 50 to 2,300 Nm. The two-, three- and four-stage

gear units only need little space due to their compact design and offer

significant advantages for the assembly with their large shaft centre

distance. Top-quality toothing makes them low-noise and durable. Apart

from corrosion resistance, the aluminium motor and gearbox housings also

offer considerable advantages for the assembly due to their little weight.

Compact drives for electric vehicles

The Sinochron drives for auxiliary units, which ABM presents in the area

of e-mobility, are energy-efficient, durable and compact. The motors have

sensorless control, are compact and cost-efficient. Electronic

controllers, which have been optimized for the special application,

considerably reduce losses in the entire use and thus increase the energy

efficiency of the system. ABM offers travel drives like the 22 / 45 kW

motor for smaller electric vehicles as well. The maximum torque of 130 Nm

establishes the pre-condition for dynamic accelerating and high driving

pleasure. The large field weakening range of the motors allows high

climbing ability and fast driving without manual transmission. Thanks to a

high power spectrum and efficient air cooling, this drive reaches

efficiencies of up to 93%.

Bevel gear units with high torque

For the industrial sector of forklift trucks, ABM shows bevel gear units

of the series TDB 254. With their high torque transmission capacity,

quiet running and longevity, they are particularly suited for mobile

applications such as forklift trucks and commissioners. The encoder

feedback developed by ABM is also new. It is a cost-efficient alternative

to concepts with potentiometer. The encoder feedback is integrated into

the intermediate flange. The encoder itself is easily accessible from the

top in case it needs servicing. This prevents soiling as it can happen in

hitherto existing solutions with encoders next to the driving wheel. The

ABM novelty can be used flexibly with different sensors. As a system

supplier in the forklift truck sector, ABM Greiffenberger offers complete,

precisely matched and highly efficient drive systems including travel and

steering motor.

The wheel hub drive of the series TDH 280 of ABM presented in Stuttgart is

suitable for the use in cleaning machines and transport systems in damp

surroundings. It is maintenance-free, robust and designed as a complete

unity of motor, brake and gearbox. It is supplied with a battery voltage

of 36 Volt and does 1.2 kW. Its compact design allows small installation

heights and makes the installation into the vehicle easy.

For the use in counterbalanced trucks up to a load of 2.0 t, ABM has

developed the steering unit SDH as a three-stage helical gearbox with

mounted AC-motor. The battery voltage is 48 Volt, the output 0.9 kW. The

geared unit as a complete motor-gearbox-unit has been designed for high

load demands and can easily be mounted in forklift trucks. The ABM

development is a cost-optimized design and convinces with an efficiency of

94%.