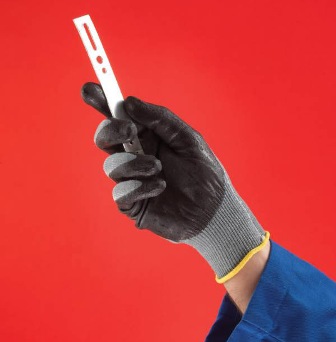

Second skin glove for delicate handling

Ansell Healthcare a global leader in hand and arm protection solutions for the industrial markets, introduces the HyFlex 11-616, an ultra-light knitted dipped multi-purpose glove. The HyFlexÒ 11-616 is 18-gauge knitted glove that forms like a second skin on the worker's hands providing outstanding comfort, fit and sensitivity while protecting his hands against abrasions. Perfect for small parts assembly, light fabrication, finishing works and packaging.

18-gauge knitting technology: comfort and precision

When it comes to selecting hand protection solutions, comfort is a becoming more and more a key factor for decision makers. After all, no matter how protective gloves may be, they are ineffective if workers do not use them due to discomfort. Hence, associating optimal comfort with the level of protection needed by the user remains the key innovation driver for Ansell.

The 18-gauge knitting technology used by Ansell for its HyFlex 11-616 glove results in an ultra-thin glove combining outstanding comfort, dexterity, fit and tactile sensitivity to a high degree of precision. The term gauge refers to the knitting machines' fineness size, which is measured by counting the number of knitting needles per inch. The recently introduced 18-gauge machines (compared to the existing 7-, 10-, 13- or 15-gauge) allow to produce ultra-thin and, therefore, the most comfortable gloves.

For the most delicate handlings

Designed for assembly tasks requiring a high degree of precision, the HyFlex 11-616 is intended for tasks involving repeated flexing and pinching of the fingers and fingertips. The level of comfort and sensitivity achieved make the glove ideal for workers who are looking for gloves offering them a higher level of fit, touch and precision than offered by their current gloves.

The HyFlex 11-616 is recommended for handling and light assembly applications. Examples include: picking or fitting small pieces such as screws, bearings, fasteners or springs; white goods handling and production; fine assembly, repair, finishing works and packaging. Use of the gloves is an excellent way to avoid deteriorating finished products.

Even in very light assembly operations, wearing ultra-thin gloves helps to avoid minor punctures (splinters, wires) and scrapes which may become infected and painful. It protects skin from the formation of blisters and even from the drying effects of wood dust or glue.