NORD Drive Systems successfully managed the challenges of achieving high manufacturing throughput and machine safety protection by utilising AS-i safety monitoring and muting from Leuze electronic.

NORD which was founded in 1965 has sales of approximately 337m€ and is headquartered in Bargteheide, near Hamburg, northern Germany. Market leaders in drive technology for gear motors and frequency inverters, NORD use AS-i technology within their products and also within their own manufacturing processes.

The AS-Interface was developed in the early nineties and is a concept that has become established as a trusted standard. AS-i is now a leader in the sensor / actuator area, being used world-wide by automation engineers to simplify their wiring jobs. Cost savings of over 30% are not uncommon and AS-i Safe is often used because the machine builder does not want the complexity and audit requirements of implementing safety control within the PLC itself.

The numbers they say speak for themselves and with over 16 million AS-Interface nodes in use, more than 1,500 certified products available, more than 300 members supporting the system and an annual turnover of 300m€ in AS-i products, AS-i can claim to be a success.

Therefore when NORD purchased a Sorting Transfer Vehicle from global material handling equipment manufacturer Daifuku, their automation specialist UCS helped them implement it using AS-i. UCS used unique products from Leuze electronic which integrate the AS-interface with muting control within their ASM units.

Muting a safety light curtain is the temporary and controlled suppression of its protective function. For example, muting allows a load to pass through a curtain without it stopping the protected machine as it would at other times.

The careful control and implementation of muting is therefore not only critical to ensure the protection of machine operators but also the overall productivity of the automated manufacturing process. For example, muting the light curtain at the wrong time or for too long might expose a machine operator to danger, whereas incorrect muting might cause an unacceptable interruption like a pallet leaving the area to trip the curtain and stop machines causing disruption or possible damage.

Because of the large size of Leuze electronic's machine safety range, they offer many muting solutions including AS-i safety monitor muting technology, which is a product of their considerable expertise as a designer and manufacturer of AS-i safe products. The AS-i muting controllers provided NORD with protection to Category 4, EN 954-1 and PLe to EN ISO 13849-1, whilst also enabling fast material flow and hence high manufacturing process efficiency.

Christian Fornée, project manager responsible for software development at UCS said, "We implement many AS-i applications, primarily on conveyor systems, where the use of frequency-controlled motors is common. Here, AS-i is the most cost-effective and functionally adequate alternative to Profibus, because often only two speeds plus reverse are required. "

NORD's application is segmented into five separate zones, three of which use AS-i Safety at Work, with the other two using conventional hard-wiring. Typically an E-STOP within the zone, will stop movement within that zone and potentially the transfer vehicles if appropriate. Therefore an AS-i controlled zone typically contains:

2 AS-i safety monitor

9 multi-beam safety light barriers

9 muting sensors

3 AS-i emergency-stop buttons

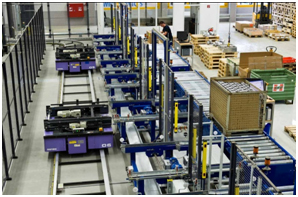

The Sorting Transfer Vehicles (STV) run along a track which has fixed guarding along most of its length, with a key controlled access door specifically provided only for the maintenance team. Euro-pallets and wire-mesh cages which arrive or depart on the main roller conveyor system are transferred to the automated transfer vehicles through one of several loading stations. Each transfer station includes safety light curtains from Leuze electronic to ensure operators do not gain access to the STV track.

NORD's application is typical in wanting to accommodate the transfer station in as small a foot-print as possible, whilst using the fast movement of parts to give manufacturing efficiency, whilst ensuring operator safety. For example the space used to temporarily park a pallet while it waits for the transfer vehicle or to join the main roller conveyor, was minimised to an extent that it presented a challenge to the system integrator UCS. The challenge was to park pallets within just 12 cm of the front of the safety light barrier, whilst delivering a system with smooth, automated transfer through several transfer stations.

Whilst a pallet waits in this parking space, the muting sensors on the safety light curtain must not be tripped, because a muting error would occur. This was overcome using the AS-i query cycle and having the muting sensors arranged with a slight offset. Because the pallet approaches at a speed of 0.5 m/s, the timing of the muting sequence is carefully controlled and monitored so that it is muted while the load passes through the light curtain.

Because not all loads on the pallets present a solid and smooth face parallel to the conveyor system itself, there were problems with the triggering of the muting sensors. After careful testing, UCS decided to perform parallel muting using a sensor signal and a machine signal. As a result, even if the load on the pallet is not parallel to the conveyor, it is still able to pass through the protective zone.

Commenting on the principle, Christian Fornée says: "AS-i Safety was used here for the first time. We chose this because we are evaluating 20 Multiple Light Beam Safety Devices for monitoring the transfer areas and eight E-STOP buttons via the safe AS-i bus. The protective sensors with AS-i connection are a very economical solution if the muting functionality is moved to the AS-i Safety Monitor. The amount of wiring required is then very low compared to conventional wiring."

Leuze electronic's integration of the muting function within the AS-i Safety Monitor provided a particularly economical and flexible automation solution through AS-i, because the muting sensors and the safety light barrier can be queried directly via AS-Interface and evaluated by the AS-i Safety Monitor. The main cost advantage here is in the control of multiple muting areas with just one AS-i Safety Monitor. To accomplish this in the past, each protective sensor needed to be provided with the muting function, or a separate muting controller was necessary for each muting area.

For access guarding, Leuze electronic also offers light guards and curtains with integrated AS-i interfaces, as well as electronic AS-i input modules for connecting normal safety light curtains. The muting sensors are simply integrated in the AS-i network via standard AS-i input slaves. The light guards and curtains which have the integrated AS-i interface can be directly connected to the AS-i cable, which considerably reduces the amount of wiring and hence installation cost.

Working in a close partnership, the system integrator UCS, the equipment manufacturer Daifuku and Leuze electronic were able to implement a muting solution for NORD utilising the benefits of AS-i. Not surprisingly all drives in the application at NORD are equipped with the company's own drive motors with decentralised inverter technology (SK 200E), which use an AS-i connection. The result is a very economical solution thanks to the AS-interface.