The UK subsidiary of German storage system and sawing machine manufacturer, KASTO, exhibited for the first time at an IMHX show this year. Managing director, Ernst Wagner, was impressed by the number and quality of enquiries from new companies and existing users, as well as from pre-existing customers that they have not been in contact with for several years.

"In Germany the market is picking up strongly and the UK is starting to follow suit," Mr Wagner said. "Interest in automation is being shown right across industry, from stockholders to manufacturers looking to feed material to their machine tools more efficiently."

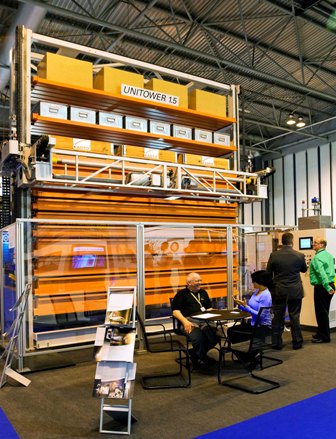

KASTO's storage products, which are available with varying degrees of automation right up to very sophisticated, high-end systems, are designed for either sheet and plate or long stock such as bar and tube. Some stores, however, are capable of accommodating both types of raw material as well as pallets and boxes. The main interest this year was in sheet storage, especially from the aluminium sector.

One of the drivers behind increased use of automated handling is current Health & Safety Executive guidance on maximum weights men and women should be allowed to lift in the workplace. These range from 25 kg down to 3 kg, according to who is lifting the load and its position relative to the body.

With a view to avoiding potential strain injury, a good enquiry at IMHX was from a stockholder considering automating the picking and banding of material from cassettes presented by a KASTO store at each of nine input / output handling stations.

KASTO is being asked more and more not only for computer-controlled, 3D storage in a small footprint, but also for robotic and other automated handling equipment for when the material exits the system. Full traceability of material together with automatic stock control and replenishment are further benefits of such solutions.