Leuze electronic's new MLD300 and MLD500 multiple light beam safety devices offer integrated lasers for the fast commissioning of perimeter guarding.

Leuze electronic's new range of Multiple Light beam safety Devices (MLD) include numerous features to make commissioning easier. One of these is the innovative use of lasers at the top and the bottom of the column to enable fast set up of perimeter guarding.

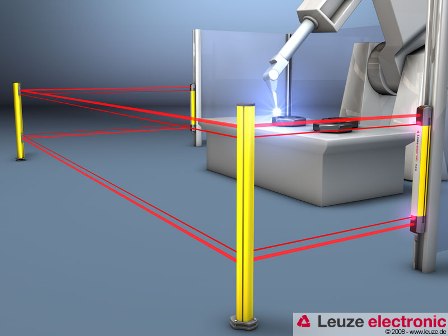

Perimeter guarding can be challenging to commission especially around large machining centres where several reflecting columns are used to cover a large distance. For example, the 2, 3 and 4-beam transmitter and receiver systems within the MLD 300 and MLD 500 families can cover a range of 70m.

Leuze electronic has for some years offered an alignment laser integrated into the top of the transmitter column. This has been especially popular with machinery manufacturers who commission their own machines, an example being a World leading manufacturer of punching machines, who talks of the alignment laser saving a couple of hours on every installation.

During the design of the new MLD 300 / MLD500 Multiple Light beam safety Devices, an ambition was to utilise the latest generation of brighter laser diodes to provide even better integrated laser alignment.

Despite the MLD range having a lower price than its predecessor, it is now possible to offer an alignment laser in both the top and bottom of the column, rather than just the top.

Another improvement in the design of the MLD range is to reduce the distance between the alignment laser and the infrared safety sensor to only 36mm, compared with 56mm previously.

To further reduce the problem of a brightly lit factory making it difficult to see where the alignment laser lands, a highly visible reflective foil strip is applied to the ideal landing area on the receiver column. It is surprising how this simple solution makes the laser much easier to see.

The MLD receiver and transmitter sets can cover 70m, with the first reflector column being up to 20m from the transmitter. Therefore, the performance improvements in the integrated alignment make the commissioning of perimeter guarding even quicker.

The extensive MLD family offers either 'Type 2', 'SIL 2', performance level 'd' protection from the MLD300 range, or 'Type 4', 'SIL3', 'PLe' from MLD500 devices. Within both ranges, there are three different levels of functionality, with many of these functions previously having only been available on more expensive units. For example the MLD 320 and MLD 520 models offer start/restart interlock, contactor monitoring and configurable operating modes, with the range topping MLD 330 and MLD 530 offering integrated control of parallel or sequential muting.

Commissioning or swapping out of the units is fast because all configuration of the MLD devices is defined by the wiring connections used, namely there is no requirement to use a PC or set DIP switches for configuration.

Installation is also made easier and hence quicker by a choice of mounting systems. A new patented system provides full flexibility of mounting height within device columns, rather than being constrained by the position of pre-drilled mounting holes.

The other mounting system is a new bayonet style of swivel mount. Zinc die-castings enable quick alignment and provide reliable mounting - examples of Leuze electronic 'the sensor people' providing industrial solutions that reduce costs.