Renowned for its innovative approach to new product development, the design and engineering team at Whale Tankers the UK's leading manufacturer of high quality vacuum tankers and jetting equipment has now developed a new anti-vibration gully boom control unit. Developed in house as part of a blue sky think tank, the radically redesigned control unit has been introduced as a means of reducing health and safety concerns surrounding hand arm HAV vibration.

Comments Whale's Senior Engineering Manager, Andy Ellis Despite the fact that our existing unit fell within the accepted daily exposure limits as laid down legislatively in the Control of Vibration at Work Regulations 2005, we share the view that if exposure to vibration and high impact shocks can be reduced further then it should be. As a result, every single component part of the new gully boom control unit has been minutely scrutinised in terms of its design and material composition, and comes as a result of extensive research into what is a complex issue.

The new unit has already been extensively trialled in the field and all new Whale Tankers are now being fitted with the new equipment as part of our standard specification. Whats more, given that operators have to ensure that all equipment in operation prior to July 2007 complies with the new regulations by July 2010, our new generation gully boom control unit is suitable for retrofitting, he added.

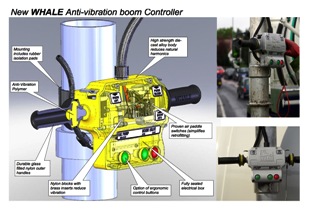

In essence, the new unit has been engineered to reduce the effects of vibration exposure, such as damage to the blood circulatory system, sensory nerves, muscles, bones and joints, and noise attenuation. In order to achieve this, deploying the use of finite element analysis (FEA) and frequency analysis simulation has led to the main body being manufactured in a robust and high strength die- alloy that takes out potentially harmful vibration frequency waves.

The same is equally applicable when it comes to the gully boom's handles, where Whale has also paid attention to the field of ergonomics. Serving to isolate the user from the main unit, Whale has developed specially designed handles that are flexible but strong enough to withstand normal operating conditions. Moulded from three specific parts, the main body of the handle and the part connected to the die- alloy body deploys the use of glass filled nylon for strength and durability. Sandwiched in-between is an injected and specially formulated polymer unique to Whale that flows into the other parts to remove shocks and vibration associated with normal use, whilst also isolating the operator's hands from vibration.

"The polymer that has been deployed to create the flexible part of the new handle is a perfect example of the lengths we at Whale will go to ensure that only the best components are used in the manufacture of our products. Given the importance of the polymer being able to absorb shocks and vibrations, a great deal of time and effort was expended into researching a vast range of types before selecting the final one," injects Andy.

Whilst Whale has retained the use of proven air operated paddle switches - for ease when retrofitting - these are now mounted on specially designed internal nylon blocks with brass inserts to help further reduce vibration during operation. The main control unit can also be supplied with electrical control buttons, including the vac pump engaged and boom valve (open and closed), if required. Not surprisingly, Whale has also paid attention to the way the anti-vibration gully boom control unit is fitted to the gully downpipe by using a bonded NBR (Natural Butane Rubber) anti-slip mounting as a means of delivering further isolation.

Concludes Andy: "The new unit not only makes life easier for the operator by reducing the potentially harmful effects of repeated exposure to vibrations and shocks, it has the added advantage of ensuring that equipment exceeds legislative requirements. What's more, a major requirement at the design stage was for existing equipment to be able to be upgraded, thereby saving customers the expense of having to opt for a completely new unit."