A section of floor at Hope Valley College, Derbyshire, can now rise up to 600mm to create an elevated platform which can be raised and lowered for special events.

Hope Valley College is a small, rural, comprehensive school based in the Peak District National Park, Derbyshire, England with a reputation as a high quality, Technology and Arts College. In 2009 it was recognised as a High Performing Specialist School and as a result it gained a third specialism, that of Applied Learning with the Gifted and Talented.

Derbyshire County Council decided that a mechanically retractable platform would be of great benefit to the college for the performing arts students as it would encourage talented students nationally to enrol at the college. The ability to have a raised platform would give the students the experience of performing on stage without compromising on the rooms flooring area for other classes.

Garrandale Limited were commissioned to design and produce the elevated platform. Formed in 1976 and also based in Derbyshire they contracted Power Jacks based in Fraserburgh, Scotland to supply the lifting mechanism. The engineering company decided to use screw jacks rather than hydraulics, because they concluded that an electro-mechanical screw jack system was cleaner, easier to maintain, easier to synchronise and more reliable and more environmentally friendly. Having worked with Power Jacks for many years, the company knew they could provide a worm gear jacking system that would raise and lower the elevated platform effectively.

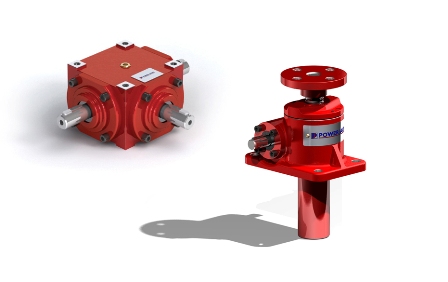

Power Jacks supplied Garrandale Limited with screw jacks, gearboxes and drive shafts.

The screw jacks are the E-Series type, which have an integrated forced grease lubrication system. This design pumps grease through the gear directly on to the flanks of the lead screw to ensure that the screw always has an optimum lubricant covering. This also lowers friction and operating temperature while increasing life. The E-Series Machine Screw Jacks are the "Classic" Single Face Screw Jacks that have proven industrial use in the most demanding applications.

They are one of the most widely used and popular screw jacks in use worldwide.

All drive shafts used were of the "self-supporting" for easy and cost effective installation. Using them meant that the screw jacks and bevel gearboxes could be directly connected to the drive shafts without any intermediary couplings or plummer blocks to support conventional drive shafts.

The ultra compact gearboxes are designed for the transmission of rotary mechanical power through ninety degrees or split power from one input drive to two or three output drives. They use precision cut spiral bevel gears to deliver a smooth and quiet transmission with an efficiency of up to 98%. All built into a robust gearbox housing optimised to minimise installation space, delivering high torque ratings and good thermal characteristics

The useable platform is approximately 4m x 4m and was designed to the specification supplied by Derbyshire County Council. It lifts a uniformly distributed load of 5kN/m2 and it can raise this load to a height of 600mm from floor level. The mechanical jacking system consists of 4 x 25kN screw jacks that are linked together by bevel gearboxes and drive shafts. To allow the top surface to sit flush with the floor in the room the platform jacking mechanism is installed into a pit. The whole assembly is powered by a single 3kW motor that drives through an 8:1 reduction gearbox with the jacks supported on fabricated steel pedestals that are secured to the floor of the pit.

These pedestals are linked together in groups of 2 providing support for the bevel gearboxes and drive motor/gearbox. On top of this jacking system sits the main platform. This platform is constructed from 2 off lengths of universal beam with lengths of square hollow section passing through holes cut in the web. Each length of universal beam spans between two jacks at 90° to the bevel gearbox supports. An access hole is also fabricated into the platform structure to allow maintenance to take place.

The sides of the platform are constructed from hard plastic faced chipboard and are attached to the steel work via folded steel bracketery. The platform and butting up to the top of the side plates are brushed stainless steel edging plates which are mounted to form a barrier for the wooden flooring to be butted up to. Mounted to the edge of the pit and facing the stainless steel plates are mild steel edging plates. These form a barrier for the flooring to butt up to, external to the platform. Two limit switches are employed to stop the platform at the top and bottom of its travel. This limit switch arrangement is mounted to the bevel gearbox support frame near the lift's motor/gearbox assembly. In the down position the platform top is flush with the floor in the room.

Darren King, a project manager, for Garrandale Limited was delighted with the results. "Working with Power Jacks ensured we provided a product that was met to the criteria set out by Derbyshire County Council,"

Bruce Hamper, Customer Services and Marketing Director also said, "This project is another good example of Power Jacks products providing high quality stage solutions. When the college's performing artists move to a bigger stage they'll know if it's Power Jacks underneath, they'll get the best support"

The platform has now been in operation for one year and is operating successfully.