Many general machinery manufacturers are ignoring a common operational problem that costs users money and wastes compressed air - but the means of solving it is easily available, thanks to global pneumatics experts SMC.

A simple principle that's often completely overlooked is whether it's really necessary for the return stroke of a pneumatically-operated cylinder to function with the same pressure as the working stroke. Design engineers at SMC found that air consumption can be cut by up to 40% after installing their series ASR and ASQ air-saving valves - but without compromising the speed at which the cylinder operates. These ingenious valves work by simply reducing the pressure required to operate the return stroke of a cylinder - which, in turn, cuts operating costs.

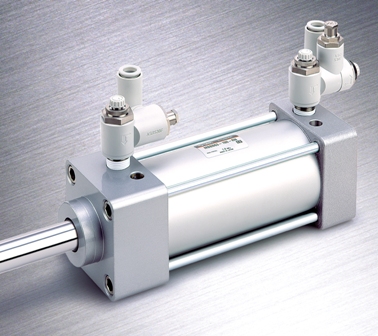

The compact profile of the valves is a key feature; in the same size as a conventional flow controller, the ASR pressure valve incorporates a miniature integrated regulator with check valve and speed controller, whilst the ASQ comprises a quick supply and exhaust valve with speed controller. Body and piping ports both rotate through 360 degrees to enable easy installation.

Finally, the valves come complete with SMC one-touch fittings for quick and easy installation so that no additional parts are needed to install this cost and energy saving solution.