PAS, a leading supplier of software products and consulting services to the processing industries worldwide, has released a new version of its comprehensive alarm management and control loop optimisation software with new features to improve plant safety and productivity.

PlantState Suite Version 6.5 provides new features to help improve process

safety and to demonstrate good practice in accordance with process safety

standards IEC 61511, ISA 84 and compliance with the OSHA 29 CFR 1910.119

rule for plants handling highly hazardous chemicals in the U.S.

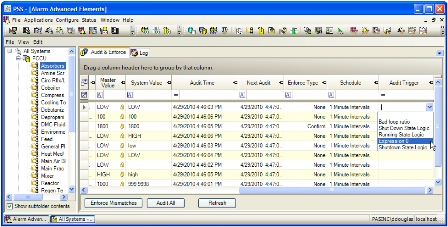

To facilitate improved process and plant safety, PlantState Suite Version

6.5 now incorporates the ability to audit and enforce control system

parameters when a pre-configured event occurs. This capability provides a

mechanism for proving the proper execution of control-system and

safety-instrumented-system shutdown routines. It acquires the necessary

information automatically, thus precluding the need to manually prove the

functionality at a subsequent time.

Change management is another important factor in safety lifecycle

management. PlantState Suite Version 6.5 is now integrated with PAS'

Integrity(tm) Software, which maps and tracks the configuration of the

industry's major control and safety instrumented systems. With this

capability, users can access control strategies and change management

details in the context of any alarm or event with a single click, thus

enabling faster and more accurate troubleshooting.

"Helping our customers to improve their safety and regulatory compliance,

while simultaneously improving their bottom line, is PAS' mission. The new

capabilities of PlantState Suite Version 6.5 are targeted specifically at

these needs," says Chris Lyden, PAS President.