Trade Fabrication Systems (TFS), one of the UK's leading processors of coated and laminated wood based products, has invested heavily in infrastructure and operations to become a one-stop operation for specialist and technically advanced wood finishes.

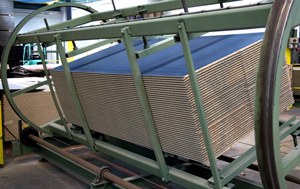

An ambitious expansion programme sees the processor invest in excess of £500,000 in state of the art coating facilities including spray and roller coating equipment that will extend TFS' core product range to include factory applied sprayed, filled and coated surface finishes, such as coloured UV lacquers. Having carved out a niche as the leading UK supplier of a diverse range of high quality floor finishes, such as peel off protective films to major panel board manufacturers, the new machinery allows TFS to deliver innovative solutions for both performance and decorative purposes.

This widens the scope of application for TFS' coated and laminated products to include bespoke surface finishes for the kitchen and furniture markets, primed and finished panels for the DIY sector, pre-primed /finished site hoardings, as well as wall panels for hotel or retail fit-outs. Combined with the recent growth of the TFS Partner Programme, to include distributors, TFS is aiming to reinforce its position in the marketplace as one of the UK's leading processors with both a diverse customer base and wide-ranging product portfolio.

To further strengthen this position TFS has devoted time to engineer internal processes that drive efficiency throughout the business and guarantee blue chip quality control procedures are maintained. In turn these robust standards ensure TFS increases manufacturing capacity and retains the ability to turn around bespoke orders in an efficient and timely manner.

Howard Morris, general manager, TFS comments: "Our objective is to strengthen the future of the business with this phased investment programme, as the state-of-the-art processing equipment not only increases the depth of our product portfolio but effectively doubles the capacity of our factory by adding what is essentially another production line. While this allows us to offer our customers even greater flexibility to fulfil bespoke orders it could also create up to six new jobs for the local area.

"Recognising that our employees are equally as important to ensure continued delivery of our excellent technical support, we are not limiting our investment to physical assets but are also investing in our human capital by working towards both Investors in People and ISO9002 quality assurance."

With a solid reputation for providing clients, such as panel board manufacturers and specialist distributors, with expert technical knowledge to jointly develop cost effective solutions that add value to a sale, the extended product range will further assist clients to fulfil their customer requirements. TFS clients can realise increased margins as adding a factory applied technically advanced coating creates a premium product. TFS has a vast portfolio of finishes including slip resistant coatings, anti-bacterial films/coatings, Class 0 fire retardant foils/coatings, peel off protective films and UV lacquers in a range of colours that combine decorative appearance with technically enhanced performance.

Furthermore, with a proven track record of successful collaborations with major panel board manufacturers and key distributors, TFS can also extend customers' own branded ranges, having already helped to develop industry leading BBA approved brands utilised throughout the UK house building industry.