Hyster has announced that wireless monitoring, the base level of its Hyster Tracker™ telemetry solution, will now be included as a standard feature on its electric and internal combustion engine (ICE) counterbalanced lift trucks, as well as selected stand-up lift trucks.

Wireless monitoring tracks key fleet metrics including lift truck utilisation, impacts, location, and diagnostic trouble codes.

The technology enables operations to schedule and track preventative maintenance and gain greater insight into the total cost of fleet operations. Seven years of wireless communication fees will also be included at no additional charge.

“Operations depend on our equipment to keep them moving in some of the toughest material handling environments on earth. Fleet managers and forklift operators are pushed to do more with less, and not just any technology can keep up.

"But the right tools can make their jobs easier by helping crews to work more efficiently and get the most out of their equipment,” said Steven LaFevers, Vice President, Global Emerging Technology at Hyster.

“The goal with making wireless monitoring standard is to equip more operations with the insights that can help them extend the life of their trucks and reduce avoidable damage, downtime and costs.”

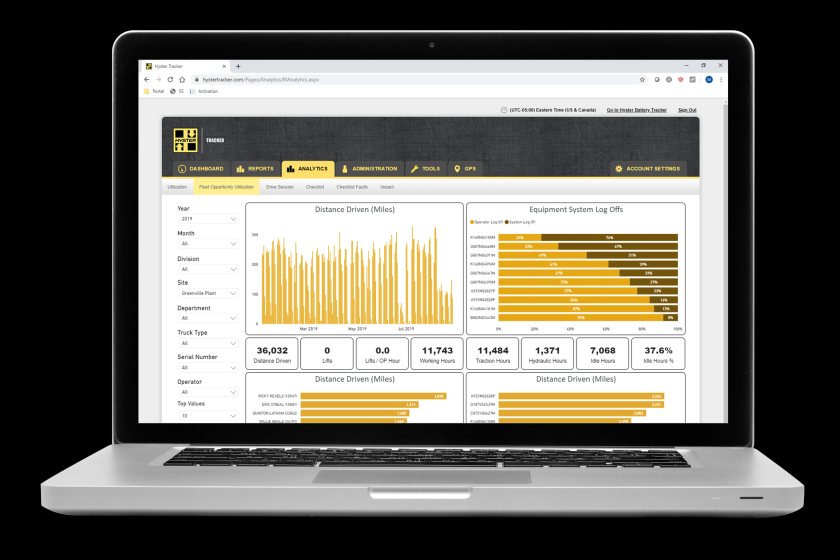

Hyster Tracker delivers real-time fleet telemetry through easy-to-use dashboards that visualise data and offer actionable insights.

The system helps improve safety by encouraging operators to follow best practices and provides businesses with full visibility of their lift truck fleets, enabling proactive issue management.

Data is stored on a cloud-based portal accessible 24/7 via any internet-enabled device.